Arch Fitters production methods combines proprietary technologies and 30 plus years of experience in manufacturing all of our custom orthotics and products.

Before we begin manufacturing, we need an accurate foot shape to process. Send us your preferred casting method:

Larger volume facilities love the speed and accuracy of our digital scanner. We are proud of our reputation of being one of the fastest central manufacture labs in the USA.

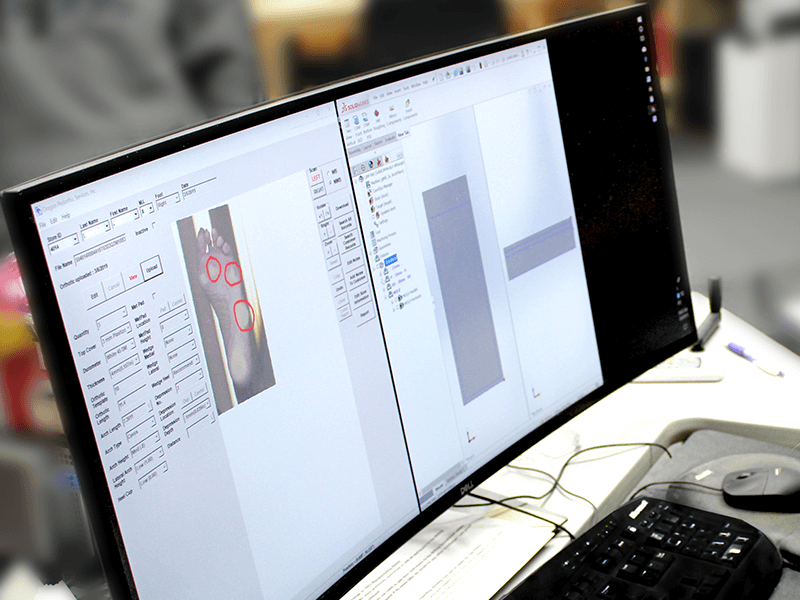

Designing the shape and function of each orthotic takes years of experience using the state of the art software, Solid Works.

Each orthotic is programmed by one of our senior orthotic designers using this extremely accurate modeling program, Solid Works, to achieve accuracy.

Wedges, heel lifts, metatarsal supports, and other options are programmed with precision. Each orthotic has 900 control points for infinite manipulation.

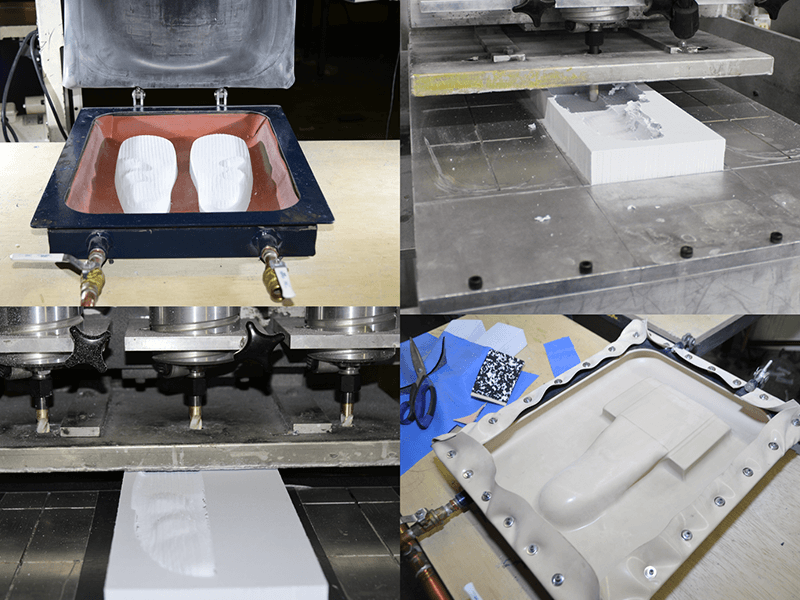

After the orthotic is designed, a wooden mold is cut out. A mold is a hard representation of a person's foot with corrections. The corrections are necessary to medically align the foot and help heal, correct, or comfort each unique foot concert. Once the mold is finished, it is prepped and put into a vacuum bladder system. This system is commonly known as vacuum forming. A layer of plastic, graphite, or EVA will form over these molds.

In most cases, the material is heated up to a certain temperature that allows it to be flexible. It is at this point the rubber bladder is closed and all air is sucked out of the unit. This causes the top rubber bladder to form over the molds forcing the material to take their new shape. Once the heated material cools long enough, the new shape becomes permanent. Thicker plastic and graphite take longer to form.

In the final state, a top cover is added and the orthotic is trimmed to the selected shoe size. There are many top covers to select from, each having a unique purpose. After the orthotic has been completed and inspected for quality insurance, it's then mailed out. This entire process takes about 48 hours.

Once we get your cast via mail or electronic upload, Arch Fitters will manufacture and ship within two business days.